Difference between revisions of "The WATA device"

(→Estimated Lifespan) |

m (Tag: Visual edit) |

||

| (34 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | {{Language-box|english_link= The WATA device | french_link= Coming soon | spanish_link= Coming soon | hindi_link= Coming soon | malayalam_link= Coming soon | tamil_link= Coming soon | swahili_link=coming soon | korean_link= Coming soon | chinese_link=WATA设备 | indonesian_link= Coming soon | japanese_link= Coming soon }} | |

| − | |||

| − | |||

| − | |||

| − | + | [[Image:Tinkisso tem with bottles.png |thumb|200px|[https://www.antenna.ch/en/water-hygiene/guinea/ Tinkisso-Antenna] employees in Guinea holding Maxi-WATA devices.]] | |

| − | The WATA device | + | The WATA device makes use of the simple process of electrolysis (electrochlorination) to produce sodium hypochlorite at a concentration of 5 grams per liter using only salt and water as inputs. As the active chlorine has a strong oxidizing power, it effectively inactivates the vast majority of disease-causing bacteria and viruses. |

| − | + | Chlorine began to be widely used as a disinfectant in the early 1900’s. It revolutionized drinking water treatment and dramatically reduced the incidence of waterborne diseases. In many countries, including the United States, chlorine remains the most widely used chemical for water disinfection. | |

| − | |||

| − | |||

| − | |||

| − | + | Sodium hypochlorite is one form of chlorine used for water disinfection. It can be manufactured in remote locations since it can be obtained through the electrolysis of salt water. In bottles of sodium hypochlorite in a wide range of sizes can be purchased from a variety of vendors in countries around the world. Chlorine concentrations range from 0.5 to 10% and each product has its own instructions for correct dosing of contaminated water. One common product containing sodium hypochlorite is liquid household bleach. | |

| − | + | The problem is that in many developing countries chlorine is imported rather than produced locally. This steeply increased the price of chlorine for the user as it adds transportation, storage, and other related costs. In addition, the quality of the sodium hypochlorite, like with many other products, degrades in quality over the course of improper handling and storage over the course of long transportation times. The WATA range devices, developed by Antenna Foundation, allows chlorine to be produced locally to provide chlorine disinfectants for individual households, health centres and hospitals, and emergency relief. | |

| − | + | Active chlorine solution is being produced using the WATA range of devices in over 100 countries. It reaches people in need through local NGOs and community groups, international organizations, municipal authorities and private enterprises. Since the WATA range of devices was first launched in 2009, Antenna Foundation is hoping to expand their reach further through partnerships, especially with local enterprises. The WATA devices have also been incorporated into development programmes led by other organizations. | |

| − | + | {| border="1" cellpadding="5" cellspacing="0" align="center" | |

| + | |- | ||

| + | ! width="50%" style="background:#efefef;" | Advantages | ||

| + | ! style="background:#f0f8ff;" | Disadvantages | ||

| + | |- | ||

| + | | valign="top" | - Local production (avoids most storage and transportation problems and environment impacts. <br> | ||

| + | - Generation of income for local communities as the local production also creates employment and local development opportunities. <br> | ||

| + | - Solar versions available for autonomous use. <br> | ||

| + | - Quality control is possible at every stage of production and use. <br> | ||

| + | - Low cost <br> | ||

| + | - Especially suitable for humanitarian response or where armed conflict has led to an embargo on chlorine gas and powder.<br> | ||

| + | - Easy to use. <br> | ||

| + | - Can be used as a disinfectant for a large range of applications (e.g. disinfecting laboratory equipment, wounds, cleaning latrines, disinfecting kitchen utensils and surfaces, washing rough fruits and vegetables etc.).<br> | ||

| + | | valign="top" | - Electricity required (but can be run with solar energy)<br> | ||

| + | - Education and training for operators are essentials, especially when using Maxi- WATA. <br> | ||

| + | - Chlorination can cause the generation of a very low concentration of toxic disinfection by-products (DBPs) in the case of disinfecting water with a high organic matter content.<br> | ||

| + | - Dosage might more difficult than with tablets <br> | ||

| + | - Only clear water can be used to produce WATA solution and the solution is only effective in treating clear water <br> | ||

| + | - The device should only be used by a responsible person familiar with the user manual for the relevant WATA device.<br> | ||

| + | - Requires wating 30 minutes after treatment before the water is ready for consumption. <br> | ||

| + | - Chlorine taste and smell | ||

| + | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | The | + | ====The WATA Range of Devices==== |

| − | + | [[File:WATA Range.jpg|thumb|200x200px|[https://www.antenna.ch/en/activities/water-hygiene/range-wata/ The range of WATA devices] and reagents]] | |

| − | + | The device comes in four models for different scales of chlorine production: Mini-WATA (0.5L of solution), WATA-Standard (2L of solution), WATA-Plus (15L of solution) and Maxi-WATA (60L of solution). The Mini-WATA, the WATA-Standard and the WATA-Plus are all capable of running off of a solar energy source allowing them to be deployed in regions that lack stable access to electricity. The devices take 2 hours to convert the brine solution to active chlorine solution. Once the process is finished, one litre of that solution is good for disinfecting 5,000 litres of water. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | - | ||

| − | - | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | The | ||

| − | |||

| − | The device comes in | ||

| − | |||

| − | |||

=====Operation===== | =====Operation===== | ||

| − | + | [[Image:WATA Instructions.png|thumb|200px|Instructions to create the salt water solution to be transformed into sodium hypochlorite. Taken from the WATA manual]] | |

| + | The device should only be used by adults. The user guide should be carefully read before use. The chlorination however should be supervised by a qualified person. | ||

| − | To prepare the brine, a (non-metallic) container is filled with clear water. A large amount of salt is added (about 400g per liter of water) and the mixture is shaken for half an hour till as much salt as possible is dissolved. To make sure the solution is saturated, there should be some salt remaining at the bottom of the container. If no excess salt is visible, more is added till the solution is saturated. | + | The only input needed for the production of sodium hypochlorite at 5 grams per liter is salt water at a concentration of 25 grams per liter. To arrive at this concentration, first prepare a brine and then mix 1 unit of brine for 3 units of clear water for the required amount of salt water. The amount of salt water needed for production varies by device. |

| + | |||

| + | To prepare the brine, a (non-metallic) container is filled with clear water. A large amount of salt is added (about 400g per liter of water) and the mixture is shaken for half an hour till as much salt as possible is dissolved. To make sure the solution is saturated, there should be some salt remaining at the bottom of the container. If no excess salt is visible, more is added till the solution is saturated. It can be stored for up to six months and can then be mixed with fresh water for production. The water used to prepare the brine solution also needs to be clear as high turbidity levels will interfere with the electrolysis process. | ||

| − | Once the salt solution is ready, the WATA device | + | Once the salt solution is ready, the WATA device should be totally immersed in the solution. Connect the WATA device to the power supply and turn on the machine. The amount of time it takes to The power supply of the WATA device (of 110V or 220V) is plugged in. The device works on 12 V direct current. It can be plugged directly into a car battery, car battery charger or solar panel. A grid or diesel generator delivering alternating current can also be used with the provided transformer. |

| − | The power supply of the WATA device (of 110V or 220V) is plugged in. The device works on 12 V direct current. It can be plugged directly into a car battery, car battery charger or solar panel. A grid or diesel generator delivering alternating current can also be used with the provided transformer. | ||

| − | + | Active chlorine is very sensitive to light and degrades relatively quickly if not stabilized for long term storage. The stabilization process involves raising the pH of the chlorine solution and will allow it to be stored up to 3 months. It can be achieved with the WataStab reagent kit. If not stabilizing the solution should be used with 24 hours if disinfecting drinking water. It can be stored for longer if destined for cleaning purposes, although the concentration will deteriorate over time and it should be measured before use to ensure an adequate level of disinfection. | |

| − | + | ====Use for Water Disinfection==== | |

| − | + | [[Image:Tinkisso team holding Wata Standard.png|thumb|right|200px| [https://www.antenna.ch/en/water-hygiene/guinea/ Antenna-Tinkisso] sells bottles of sodium hypochlorite for water disinfection under the brand name Chlor'C.]] | |

| + | When sodium hypochlorite is added to water the active chlorine is involved in three separate reactions: | ||

| + | *Active chlorine reacts through oxidation with organic matter and pathogens in the water and kills them. This portion is called consumed chlorine. | ||

| + | *Some chlorine reacts with other organic matter and forms new chlorine compounds. This portion is called combined chlorine. | ||

| + | *Excess chlorine that is not consumed or combined remains in the water. This portion is called free residual chlorine (FRC). The free residual chlorine helps prevent recontamination of the treated water. | ||

| − | + | After the chlorine is added the water should be shaken or stirred thoroughly and left for 30 minutes. After this time, there should be 0.5-1.0 mg/L of free residual chlorine (FRC) left. This is the minimum level of FRC is needed to ensure adequate disinfection. The FRC levels can be measured using the WataBlue reagent. | |

| − | |||

| − | + | Note that the effectiveness of chlorine for disinfecting water depends on the turbidity, the organic matter content, the temperature and the pH of the water being treated. For high turbidity levels (>5 turbidity units), the water should use a filtration or sedimentation technique to remove excess suspended solids before adding chlorine. This is because the suspended solids will consume the active chlorine needed for inactivation of microbes. | |

| − | The treated water should be stored in a clean, opaque, closed container. | + | The chlorine concentrate produced is not very dangerous; it is less toxic than bleach. In case of skin or eye contact, rinse well with water. Prolonged inhalation of the chlorine fumes could be dangerous. It should be kept away from children. The treated water should be stored in a clean, opaque, closed container. The WATA device, equipment, and containers used should be rinsed thoroughly after every procedure. |

| − | ==== | + | ====Other Applications==== |

| − | The | + | The chlorine concentrate is suitable for various applications apart from disinfecting water (chlorine refers to sodium hypochlorite at 5 grams of active chlorine per liter): |

| − | + | *Dakin’s solution for disinfecting wounds: No dilution (use full concentration of active chlorine at 5 grams per liter) | |

| − | + | *To clean floors, bathrooms or latrines: 1 part chlorine is diluted with 2 parts water. It needs 5 minutes to react, after which it is rinsed with drinking water. | |

| − | + | *To wash hands: 1 part chlorine is diluted with 11 parts water. It needs 5 minutes to react, after which the food should be rinsed with drinking water. | |

| − | |||

| − | |||

| − | * | ||

| − | |||

| − | |||

| − | |||

| − | * | ||

| − | |||

| − | * | ||

| − | |||

| − | |||

| − | |||

====Maintenance==== | ====Maintenance==== | ||

| − | + | Devices need to be rinsed after each procedure with clean water. If after several uses you notice white marks on the WATA, prepare a mixture of 50% vinegar (or lemon juice) and 50% clean water. For the Mini-WATA and WATA-Standard, leave the device to soak for several hours (overnight for example) and then rinse it with clear water. Never scrub the titanium plates. WATA-Plus and Maxi-WATA need to be soaked for at least 24 hours and be completely immersed in 6-10 liters of the same vinegar & clean water mixture. | |

====Estimated Lifespan==== | ====Estimated Lifespan==== | ||

| − | + | Properly used, well maintained and carefully stored after each use, WATA devices are designed to operate for 10,000 operating hours, or around 5 years of use. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | ====Costs==== | ||

| + | Visit the Watatechnology.com webshop for the pricing of the WATA range of devices: [https://watatechnology.com/en/order/] | ||

| − | == | + | ====Field Experiences==== |

| − | + | [[Image:WATA device in Spring Health.png|thumb|200px| The WATA-Standard is the source of chlorine used to disinfect the drinking water [http://www.paulpolak.com/_slide/spring-heath/ Spring Health] delivers to rural households in Odisha, India.]] | |

| − | * [ | + | The WATA range of devices is being used in over 100 countries including: Angola, Bangladesh, Benin, Burkina Faso, Burundi, Cambodia, Cameroon, Central African Republic, Chile, Congo-Brazzaville, Côte d'Ivoire, Democratic Republic of Congo, Djibouti, Ecuador, Guinea Conakry, Haiti, India, Iran, Italy, Kenya, Laos, Madagascar, Mali, Mauritania, Mozambique, Myanmar, Nepal, Niger, Reunion, San Salvador, Senegal, Sierra Leone, Sri Lanka, Sudan, Tajikistan, Tanzania, Togo, Uganda, Vietnam and Zimbabwe. |

| − | + | *'''Guinea:''' Tinkisso-Antenna sells 250 mL flaks of sodium hypochlorite solution produced with WATA devices across the country. More information on Tinkisso-Antenna’s work here: [https://www.antenna.ch/en/water-hygiene/guinea/] | |

| − | + | *'''India:''' Antenna Foundation has two partners in India using two different business models to bring chlorine to rural households. Spring Health delivers drinking water to rural households that has been chlorinated with sodium hypochlorite produced using the WATA device. TARA produces sodium hypochlorite, bottles it and then uses a network of micro franchisors and partners to reach the end consumer in rural households. More information on Antenna Foundation’s work with Spring Health and TARA available here: [https://www.antenna.ch/en/activities/water-hygiene/india/] | |

| − | == | + | ====Further Reading==== |

| + | * WATA devices and reagents tutorial videos : [https://www.youtube.com/playlist?list=PLLCDBpdIkWj1W4UtNrMnV5Eiblhl1eslm] | ||

| + | * Short video on the WATA device produced by Antenna Foundation for World Water Day 2017: [https://www.youtube.com/watch?v=nNTr8wJqooM] | ||

| + | * Antenna Foundation’s Water & Hygiene department: [https://www.antenna.ch/en/water-hygiene/] | ||

| + | * Frequently Asked Questions (FAQ) about the WATA range of devices: [https://watatechnology.com/fr/faq/] | ||

Latest revision as of 16:49, 25 October 2022

| |

|

|

|

|

|

|

|

|

|

The WATA device makes use of the simple process of electrolysis (electrochlorination) to produce sodium hypochlorite at a concentration of 5 grams per liter using only salt and water as inputs. As the active chlorine has a strong oxidizing power, it effectively inactivates the vast majority of disease-causing bacteria and viruses.

Chlorine began to be widely used as a disinfectant in the early 1900’s. It revolutionized drinking water treatment and dramatically reduced the incidence of waterborne diseases. In many countries, including the United States, chlorine remains the most widely used chemical for water disinfection.

Sodium hypochlorite is one form of chlorine used for water disinfection. It can be manufactured in remote locations since it can be obtained through the electrolysis of salt water. In bottles of sodium hypochlorite in a wide range of sizes can be purchased from a variety of vendors in countries around the world. Chlorine concentrations range from 0.5 to 10% and each product has its own instructions for correct dosing of contaminated water. One common product containing sodium hypochlorite is liquid household bleach.

The problem is that in many developing countries chlorine is imported rather than produced locally. This steeply increased the price of chlorine for the user as it adds transportation, storage, and other related costs. In addition, the quality of the sodium hypochlorite, like with many other products, degrades in quality over the course of improper handling and storage over the course of long transportation times. The WATA range devices, developed by Antenna Foundation, allows chlorine to be produced locally to provide chlorine disinfectants for individual households, health centres and hospitals, and emergency relief.

Active chlorine solution is being produced using the WATA range of devices in over 100 countries. It reaches people in need through local NGOs and community groups, international organizations, municipal authorities and private enterprises. Since the WATA range of devices was first launched in 2009, Antenna Foundation is hoping to expand their reach further through partnerships, especially with local enterprises. The WATA devices have also been incorporated into development programmes led by other organizations.

| Advantages | Disadvantages |

|---|---|

| - Local production (avoids most storage and transportation problems and environment impacts. - Generation of income for local communities as the local production also creates employment and local development opportunities. |

- Electricity required (but can be run with solar energy) - Education and training for operators are essentials, especially when using Maxi- WATA. |

Contents

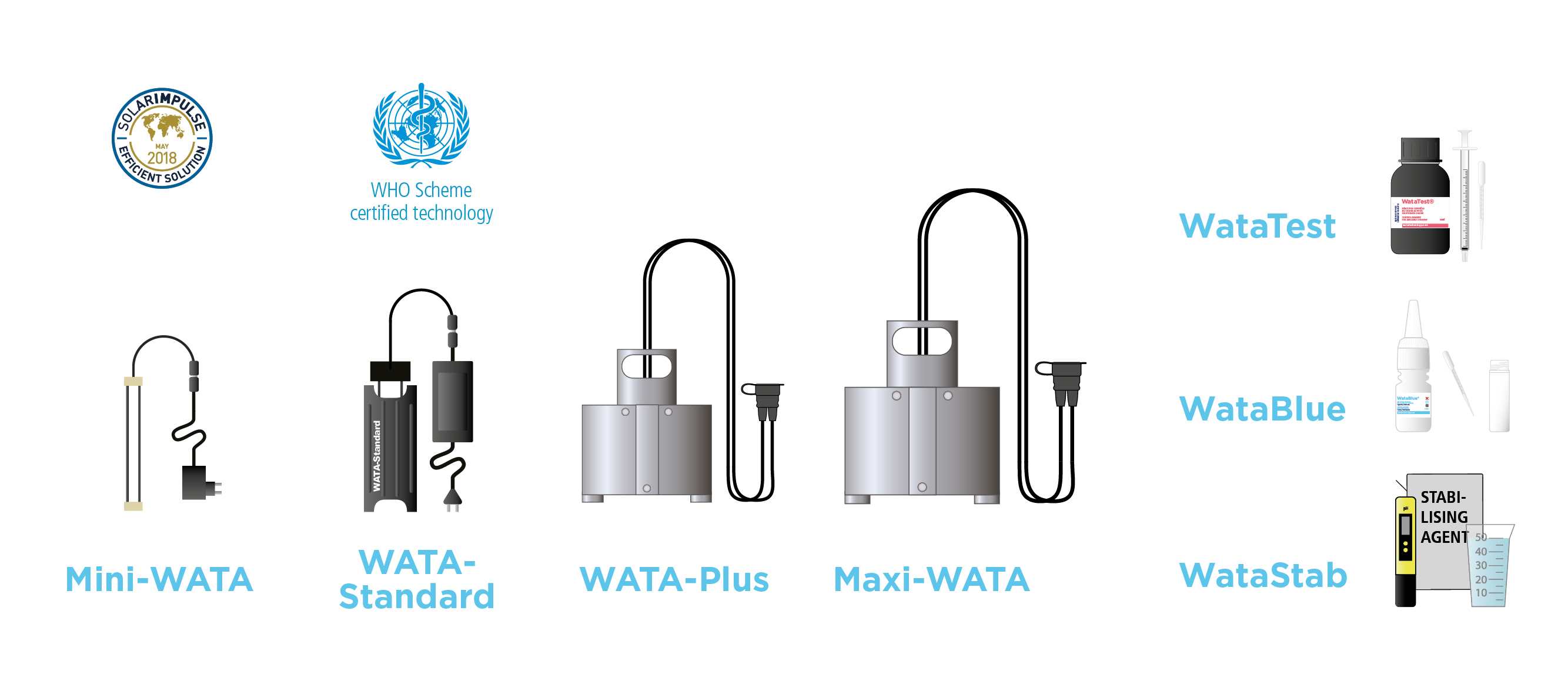

The WATA Range of Devices

The device comes in four models for different scales of chlorine production: Mini-WATA (0.5L of solution), WATA-Standard (2L of solution), WATA-Plus (15L of solution) and Maxi-WATA (60L of solution). The Mini-WATA, the WATA-Standard and the WATA-Plus are all capable of running off of a solar energy source allowing them to be deployed in regions that lack stable access to electricity. The devices take 2 hours to convert the brine solution to active chlorine solution. Once the process is finished, one litre of that solution is good for disinfecting 5,000 litres of water.

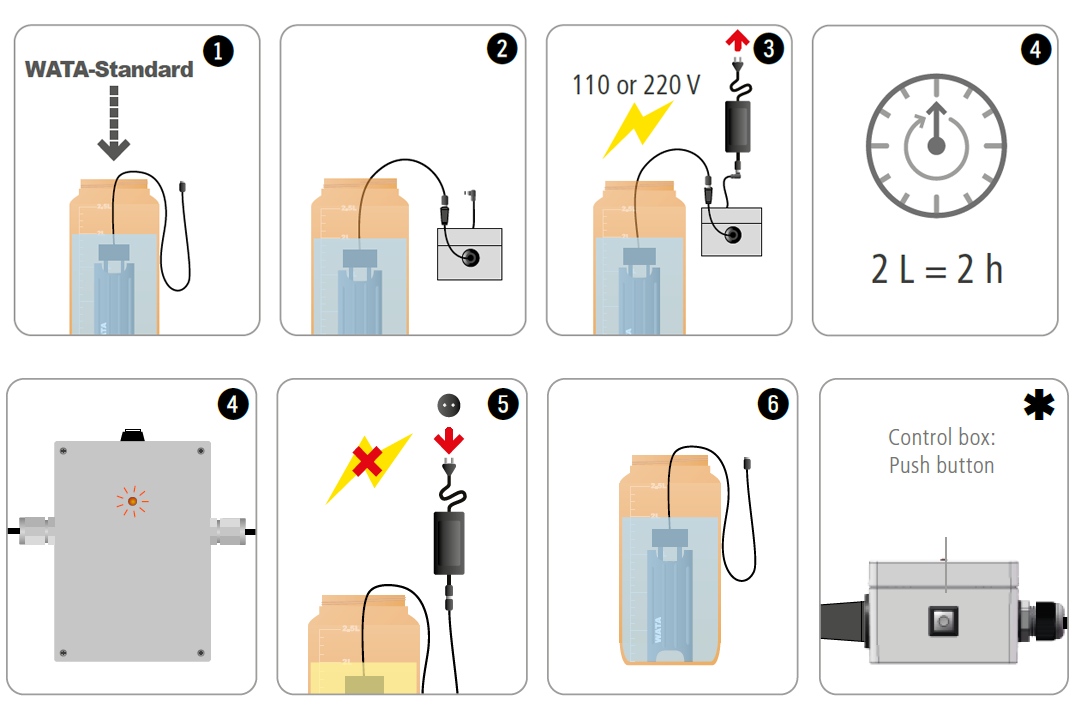

Operation

The device should only be used by adults. The user guide should be carefully read before use. The chlorination however should be supervised by a qualified person.

The only input needed for the production of sodium hypochlorite at 5 grams per liter is salt water at a concentration of 25 grams per liter. To arrive at this concentration, first prepare a brine and then mix 1 unit of brine for 3 units of clear water for the required amount of salt water. The amount of salt water needed for production varies by device.

To prepare the brine, a (non-metallic) container is filled with clear water. A large amount of salt is added (about 400g per liter of water) and the mixture is shaken for half an hour till as much salt as possible is dissolved. To make sure the solution is saturated, there should be some salt remaining at the bottom of the container. If no excess salt is visible, more is added till the solution is saturated. It can be stored for up to six months and can then be mixed with fresh water for production. The water used to prepare the brine solution also needs to be clear as high turbidity levels will interfere with the electrolysis process.

Once the salt solution is ready, the WATA device should be totally immersed in the solution. Connect the WATA device to the power supply and turn on the machine. The amount of time it takes to The power supply of the WATA device (of 110V or 220V) is plugged in. The device works on 12 V direct current. It can be plugged directly into a car battery, car battery charger or solar panel. A grid or diesel generator delivering alternating current can also be used with the provided transformer.

Active chlorine is very sensitive to light and degrades relatively quickly if not stabilized for long term storage. The stabilization process involves raising the pH of the chlorine solution and will allow it to be stored up to 3 months. It can be achieved with the WataStab reagent kit. If not stabilizing the solution should be used with 24 hours if disinfecting drinking water. It can be stored for longer if destined for cleaning purposes, although the concentration will deteriorate over time and it should be measured before use to ensure an adequate level of disinfection.

Use for Water Disinfection

When sodium hypochlorite is added to water the active chlorine is involved in three separate reactions:

- Active chlorine reacts through oxidation with organic matter and pathogens in the water and kills them. This portion is called consumed chlorine.

- Some chlorine reacts with other organic matter and forms new chlorine compounds. This portion is called combined chlorine.

- Excess chlorine that is not consumed or combined remains in the water. This portion is called free residual chlorine (FRC). The free residual chlorine helps prevent recontamination of the treated water.

After the chlorine is added the water should be shaken or stirred thoroughly and left for 30 minutes. After this time, there should be 0.5-1.0 mg/L of free residual chlorine (FRC) left. This is the minimum level of FRC is needed to ensure adequate disinfection. The FRC levels can be measured using the WataBlue reagent.

Note that the effectiveness of chlorine for disinfecting water depends on the turbidity, the organic matter content, the temperature and the pH of the water being treated. For high turbidity levels (>5 turbidity units), the water should use a filtration or sedimentation technique to remove excess suspended solids before adding chlorine. This is because the suspended solids will consume the active chlorine needed for inactivation of microbes.

The chlorine concentrate produced is not very dangerous; it is less toxic than bleach. In case of skin or eye contact, rinse well with water. Prolonged inhalation of the chlorine fumes could be dangerous. It should be kept away from children. The treated water should be stored in a clean, opaque, closed container. The WATA device, equipment, and containers used should be rinsed thoroughly after every procedure.

Other Applications

The chlorine concentrate is suitable for various applications apart from disinfecting water (chlorine refers to sodium hypochlorite at 5 grams of active chlorine per liter):

- Dakin’s solution for disinfecting wounds: No dilution (use full concentration of active chlorine at 5 grams per liter)

- To clean floors, bathrooms or latrines: 1 part chlorine is diluted with 2 parts water. It needs 5 minutes to react, after which it is rinsed with drinking water.

- To wash hands: 1 part chlorine is diluted with 11 parts water. It needs 5 minutes to react, after which the food should be rinsed with drinking water.

Maintenance

Devices need to be rinsed after each procedure with clean water. If after several uses you notice white marks on the WATA, prepare a mixture of 50% vinegar (or lemon juice) and 50% clean water. For the Mini-WATA and WATA-Standard, leave the device to soak for several hours (overnight for example) and then rinse it with clear water. Never scrub the titanium plates. WATA-Plus and Maxi-WATA need to be soaked for at least 24 hours and be completely immersed in 6-10 liters of the same vinegar & clean water mixture.

Estimated Lifespan

Properly used, well maintained and carefully stored after each use, WATA devices are designed to operate for 10,000 operating hours, or around 5 years of use.

Costs

Visit the Watatechnology.com webshop for the pricing of the WATA range of devices: [1]

Field Experiences

The WATA range of devices is being used in over 100 countries including: Angola, Bangladesh, Benin, Burkina Faso, Burundi, Cambodia, Cameroon, Central African Republic, Chile, Congo-Brazzaville, Côte d'Ivoire, Democratic Republic of Congo, Djibouti, Ecuador, Guinea Conakry, Haiti, India, Iran, Italy, Kenya, Laos, Madagascar, Mali, Mauritania, Mozambique, Myanmar, Nepal, Niger, Reunion, San Salvador, Senegal, Sierra Leone, Sri Lanka, Sudan, Tajikistan, Tanzania, Togo, Uganda, Vietnam and Zimbabwe.

- Guinea: Tinkisso-Antenna sells 250 mL flaks of sodium hypochlorite solution produced with WATA devices across the country. More information on Tinkisso-Antenna’s work here: [2]

- India: Antenna Foundation has two partners in India using two different business models to bring chlorine to rural households. Spring Health delivers drinking water to rural households that has been chlorinated with sodium hypochlorite produced using the WATA device. TARA produces sodium hypochlorite, bottles it and then uses a network of micro franchisors and partners to reach the end consumer in rural households. More information on Antenna Foundation’s work with Spring Health and TARA available here: [3]