Difference between revisions of "The WATA device"

(→Country Experiences) |

|||

| Line 1: | Line 1: | ||

__NOTOC__ | __NOTOC__ | ||

| + | [[Image:safe_water_systems_icon.png|right]] | ||

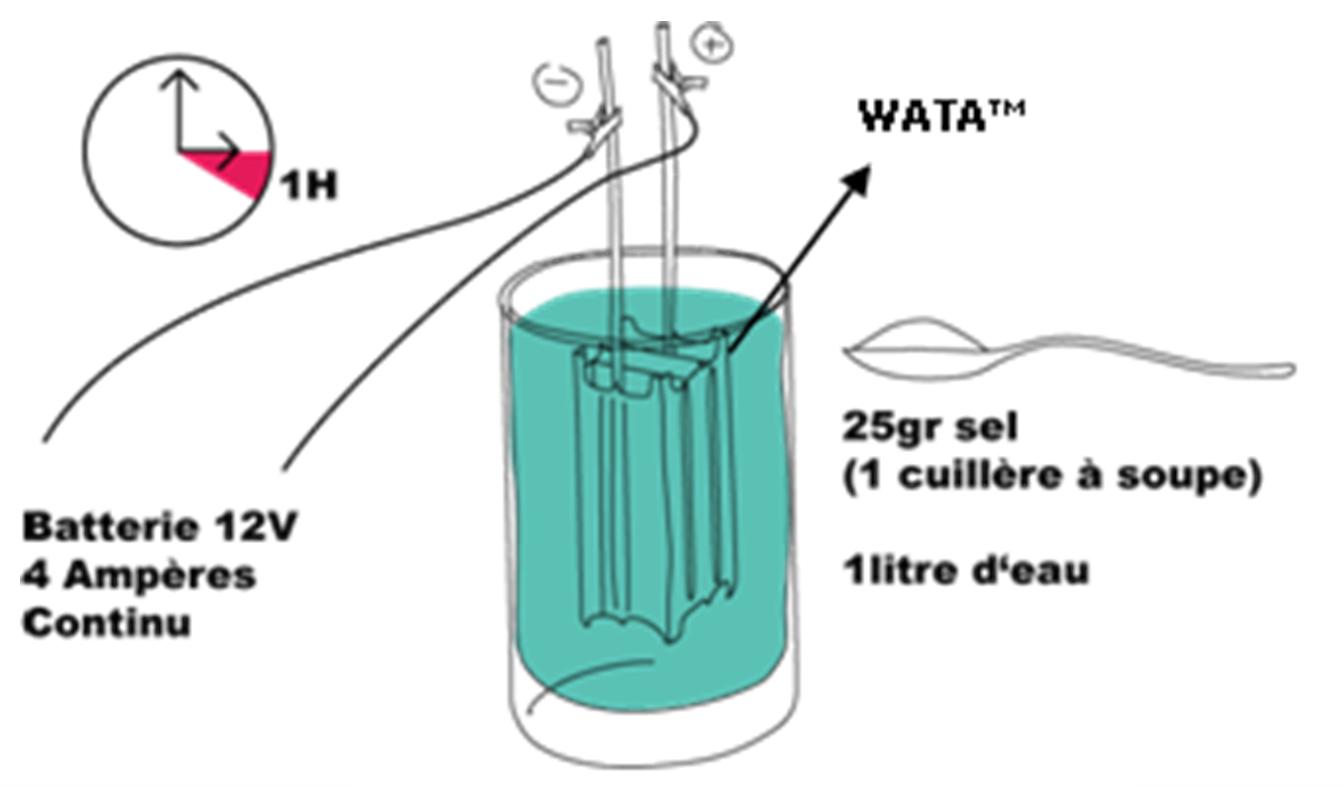

[[Image:setup of WATAsol.jpg|thumb|right|250px|Setup of WATAsol, with electrodes in salt water.]] | [[Image:setup of WATAsol.jpg|thumb|right|250px|Setup of WATAsol, with electrodes in salt water.]] | ||

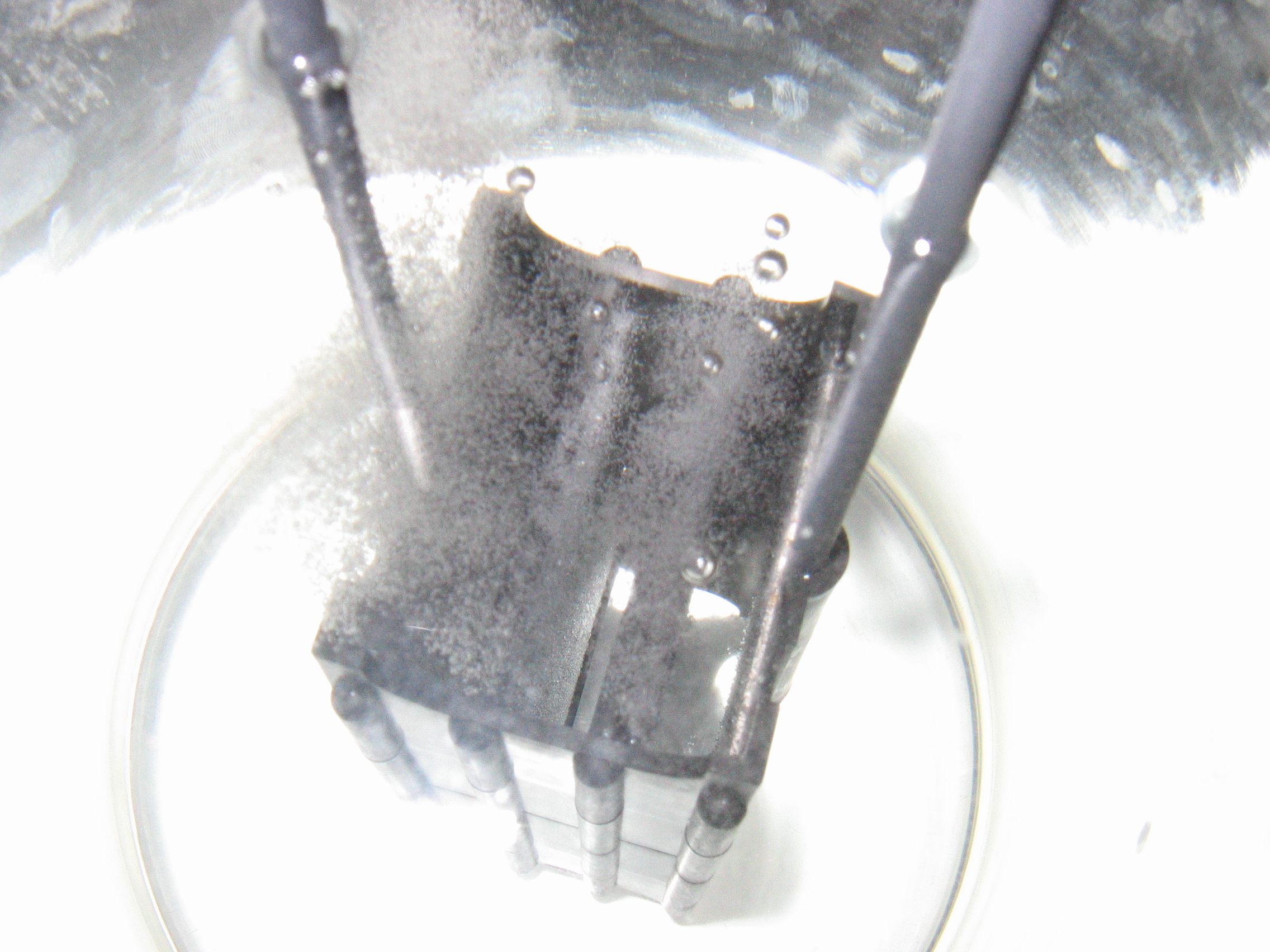

[[Image:Bubbles.jpg|thumb|right|250px|Bubbles produced during electrolysis.]] | [[Image:Bubbles.jpg|thumb|right|250px|Bubbles produced during electrolysis.]] | ||

Revision as of 20:14, 23 May 2012

The Watasol is simple a device which produces active chlorine from salt water using electrolysis. The device consists of two tungsten electrodes in a plastic container, and a transformer. The active chlorine forms hydrochloric acid when added to water. As the active chlorine has a very strong oxidizing power, is destroys almost all pathogenic germs including diarrhoeal diseases, dysentery, cholera, typhoid fever, salmonellosis and hepatitis A.

The WATA device and its use was designed by Antenna Technologies based on the norms of the World Health organization on for example the accepted quality of water, amount of chlorine needed to disinfect 1L of water and the acceptable amount of free residual chlorine.

When chlorine is added to water, it has three separate effects:

- Some chlorine reacts through oxidation with organic matter and pathogens in the water and kills them. This portion is called consumed chlorine.

- Some chlorine reacts with other organic matter and forms new chlorine compounds. This portion is called combined chlorine.

- Excess chlorine that is not consumed or combined remains in the water. This portion is called free residual chlorine (FRC). The free residual chlorine helps prevent recontamination of the treated water.

Chlorine began to be widely used as a disinfectant in the early 1900’s. It revolutionized drinking water treatment and dramatically reduced the incidence of waterborne diseases. In many countries, among which the United States, chlorine remains the most widely used chemical for water disinfection.

Sodium hypochlorite is one form of chlorine used for water disinfection. It can be manufactured in most locations since it can be obtained through the electrolysis of salt water. Bottles can be purchased for household water treatment from many manufacturers in various sizes. Chlorine concentrations range from 0.5 to 10% and each product has its own instructions for correct dosing of contaminated water. Liquid household bleach also contains sodium hypochlorite, and is widely available.

The problem is that in many developing countries, chlorine is imported, rather than produced locally. This increases the price tremendously as it adds transportation, storage, and other related costs. Often also the source and transportation is not reliable in certain remote areas. The WATAsol devices, developed by Antenna Technologies allow chlorine to be produced locally, on different scales to provide chlorine disinfectants for individual households, health centres and hospitals, and emergency relief.

WATAsol is now being produced in around 50 countries. It reaches the people in need through local NGOs, and local community and private enterprises. Starting from 2009, Antenna Technologies is hoping to expand their reach further through partnership-franchises with local enterprises as partners. The WATAsol has also been incorporated in development programmes led by other organizations.

Suitable Conditions

The concentrate is suitable for various applications:

- To wash food: 1 part concentrate is diluted with 100 parts water. It needs 5 minutes to react, after which the food should be rinsed with drinking water.

- To clean dishes, kitchen utensils, work surfaces: 1 part concentrate is diluted with 5 parts water. It takes 5 minutes to react, after which it is rinsed with drinking water.

- To clean floors, bathrooms or latrines: 1 part concentrate is diluted with 3 parts water. It needs 5 minutes to react, after which it is rinsed with drinking water.

- To disinfect pipettes, tubes or other laboratory equipment: 1 part concentrate is diluted with 1 part water. It needs at least 12 hours to react, after which it should be rinsed with drinking water.

The concentrate can be used for disinfection of barns, cow sheds and their waste water, clothes and fabrics, gutters and roads, and treatment of mycosis fungicides. Though it can be used for the disinfection of surgical equipment, it must be noted that it cannot be used to sterilize these. They must be sterilized in an autoclave or a dry-heat sterilizer.

| Advantages | Disadvantages/limitations |

|---|---|

| -It allows for the local production of active chlorine, which is much cheaper than importing bleach tablets or other forms of chlorine, as it saves on import tariffs, transportation and storage costs. - The local production also creates employment and local development opportunities. For example, the chlorine concentrate produced can be sold to local health clinics, etc. for cleaning of equipment. |

- The chlorine concentrate cannot eliminate contamination from chemical pollutants such as pesticides, fertilizers, or heavy metals. - When used on surgical equipment, it does not fully sterilize these, but it does disinfect. |

Construction, operations and maintenance

The effectiveness of chlorine depends on the turbidity, the organic matter content, the temperature and the pH of the water being treated. For high turbidity levels, the water should first be filtered through a cloth or sedimented before adding chlorine. These processes will remove some of the suspended particles and improve the reaction between the chlorine and pathogens.

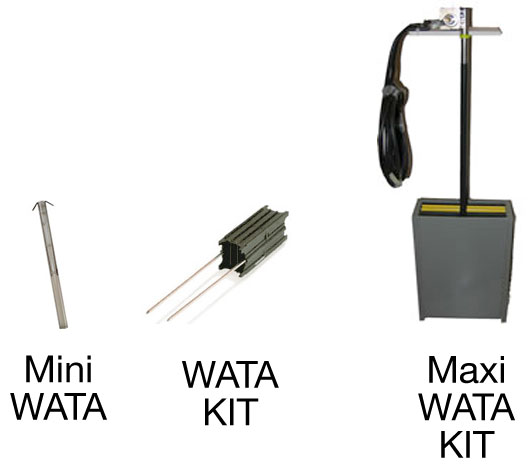

The device comes in three types, to be used for different scales of chlorine production: the WATA kit, the mini-WATA and the maxi-WATA. The mini-WATA is a variation of the WATAsol that fits into a regular water bottle. It produces active chlorine to treat up to 4800 litres of water per day, which is enough clean water for the daily needs of 240 people. It can run on 5V/1A but requires a minimum of 10W. The regular WATA produces enough water to treat 48,000 litres of water per day, providing clean water for 2400 people. It runs on 12V/4A. The maxi-WATA produces chlorine to treat 720,000 litres of water, providing for 36,000 people. It runs on a 24V/30A electric network.

WATA devices can produce between 1.2 litres and 180 litres of active chlorine each day. Each litre of that solution is good for disinfecting 4,000 litres of water. The regular WATAsol produces 1L/hr of active chlorine. It is designed to produce 2-10L per procedure.

Operation

To produce the chlorine concentrate, first a salt solution needs to be made. If highly refined salt is used, this can be directly mixed with fresh water at a concentration of 25g/L and stirred until fully dissolved to produce the salt solution. If the salt is not fully refined, it is first made into saturated brine and then mixed into the solution to be electrolyzed at a concentration of 80ml/L; such that about 1/13 of the solution is brine. Both procedures lead to the same concentration of salt in the solution.

To prepare the brine, a (non-metallic) container is filled with clear water. A large amount of salt is added (about 400g per liter of water) and the mixture is shaken for half an hour till as much salt as possible is dissolved. To make sure the solution is saturated, there should be some salt remaining at the bottom of the container. If no excess salt is visible, more is added till the solution is saturated. This can then be mixed with the fresh water.

Once the salt solution is ready, the WATA device is immersed. The body of the WATA should be completely covered by the solution but the stems should stick out above the surface. The power supply of the WATA device (of 110V or 220V) is plugged in. The device works on 12 V direct current. It can be plugged directly into a car battery, car battery charger or solar panel. A grid or diesel generator delivering alternating current can also be used with the provided transformer.

If the electrolysis is occurring properly, bubbles are formed immediately. The electrolysis takes an hour per litre, producing a chlorine concentrate of 6g/L. The chlorine concentrate should be used within three weeks of production. Notable is that full containers last longer than half-empty ones, due to the effects of dissolving oxigen.

Use

The chlorine concentrate is then added to the water to be disinfected. It should be shaken thoroughly and left for 30 minutes. There should be 0.5-1.0mg/L of residual chlorine left. The level of chlorine can be measured using the WATAblue reagent.

Especially if the chlorine concentrate is to be sold after production, it is useful to check the concentration of the active chlorine. This can be done using the WATATest reagent. The concentrate should be stored in the container provided, tightly closed and clearly labeled with the production date. It should be stored in a dark place, away from the sun. The container should be kept full if possible, since air will oxidize the concentrate.

The chlorine concentrate produced is not very dangerous, it is less toxic than bleach. In case of contact, rinse well with water. Inhalation could be dangerous. It should be kept away from children.

The treated water should be stored in a clean, opaque, closed container. The WATA device, equipment, and containers used should be rinsed thoroughly after every procedure.

Manufacturing

The WATA device is a registered product from Antenna Technologies. The WATA kit includes:

- Power supply (12V/ 5A)

- Electric transformer

- 50ml and 5ml syringe

- Spoon to measure salt (± 25g)

- Opaque plastic recipient container (±2.5L)

Extra materials needed to produce chlorine concentrate are:

- Salt

- Clear, fresh water

- Containers for salt solution and brine, and treated water.

- Power source (car battery, solar panel, etc.)

No particular experts or trained workers are required for production of chlorine concentrate. The device should only be used by adults. The user guide should be carefully read before use. The chlorination however should be supervised by a qualified person.

Maintenance

It is advisable to treat the WATA device after about 150 hours of use. The mini-WATA and regular WATA can be treated by immersing them in a container filled with lemon juice or vinegar for a night. The maxi-WATA needs to be treated with diluted sulphuric acid or hydrochloric acid.

Estimated Lifespan

The WATA device is expected to operate for about 20,000 hours. If used for 12 hours a day, 7 days a week, it would last about 4.5 years.

Costs

Excluding shipping, the costs are:

- Mini-WATA kit: 40 euros

- WATA kit: 200 euros

- Maxi-WATA kit: 1700 euros

- WATA blue reagent: free if a WATA kit is bought

- WATATest reagent: free if a WATA kit is bought

After the initial set-up costs, the cost of using a WATA kit has been estimated at 0.01 euros per litre of concentrate, cleaning 4000 litres of water.

Field Experiences

The WATAsol has been supplied to partners and is being used in around 50 countries including: Angola, Bangladesh, Benin, Burkina Faso, Burundi, Cambodia, Cameroon, Central African Republic, Chile, Congo-Brazzaville, Côte d'Ivoire, Democratic Republic of Congo, Djibouti, Ecuador, Guinea Conakry, Haiti, India, Iran, Italy, Kenya, Laos, Madagascar, Mali, Mauritania, Mozambique, Myanmar, Nepal, Niger, Reunion, San Salvador, Senegal, Sierra Leone, Sri Lanka, Sudan, Tajikistan, Tanzania, Togo, Uganda, Vietnam and Zimbabwe.

Mali

In Mali, Antenna Technologies is working with the local NGO Formations Sans Frontieres, on a programme to provide 10 health centres with WATA devices to take care of the hygiene in the centres as well as provide safe drinking water to the community.

Nepal

In Nepal, they launched a project together with the ECCA, Environmental Camps for Conservation Awareness. It will provide WATA kits to schools in poor and rural areas throughout Nepal.

DMC

In the Democratic Republic of Congo, Antenna supports a women-led programme which provides education and WATA kits to individual households, to ensure safe water on a household level and reduce common waterborne diseases such as cholera.

Reference manuals, videos, and links

- WATA kit manuals, provided by Antenna Technologies.

- Quality control reagent manuals, provided by Antenna Technologies.

- Description of the WATA device on the website of Antenna Technologies.

- Akvo water solution of the week 3.