Difference between revisions of "Jetting - Engine powered rotary jetting"

| Line 1: | Line 1: | ||

{{stub}} | {{stub}} | ||

[[Image:Treadle_pump_icon.png|right]] | [[Image:Treadle_pump_icon.png|right]] | ||

| − | |||

__NOTOC__ | __NOTOC__ | ||

Engine powered rotary jetting is a [[Jetting - general| jetting technique]] in which engine power is used to rotate the drill stem and pump the mud. | Engine powered rotary jetting is a [[Jetting - general| jetting technique]] in which engine power is used to rotate the drill stem and pump the mud. | ||

| Line 21: | Line 20: | ||

==Construction, operations and maintenance== | ==Construction, operations and maintenance== | ||

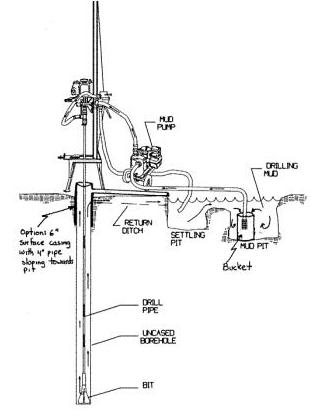

| + | [[Image:Diagram of the LS100.jpg|thumb|right|250px|Diagram of the LS100]] | ||

[[Image:PAT drill 201.jpg|thumb|right|250px|PAT drill 201]] | [[Image:PAT drill 201.jpg|thumb|right|250px|PAT drill 201]] | ||

[[Image:Self made rotary rig.jpg|thumb|right|250px|Self made rotary rig]] | [[Image:Self made rotary rig.jpg|thumb|right|250px|Self made rotary rig]] | ||

| Line 39: | Line 39: | ||

==Acknowledgements== | ==Acknowledgements== | ||

| − | |||

| − | |||

Revision as of 19:30, 27 April 2012

| |

Engine powered rotary jetting is a jetting technique in which engine power is used to rotate the drill stem and pump the mud.

A large variety of engine powered rotary jetting rigs are used. Examples of commercial versions used in developing countries are the Lone Star 100, the PAT Drill 201 and the Deep Rock Hydra drill; but many more exist.

Although one would expect a large advantage over manual jetting, engine operated rotary jetting requires the same time and reaches the same depths as the manual operated rotary jetting. The systems show better performance only with regard to ergonomic aspects.

Suitable conditions

Suitable for weakly cohesive sands and silts.

| Advantages | Disadvantages/limitations |

|---|---|

| - Better performance with regard to ergonomic aspects than manual jetting rigs | - Does not increase speed or depth as compared to manual operate rotary jetting rigs. |

Construction, operations and maintenance

A self made engine-driven rotary rig is not very difficult to make, although drill bits, drill pipes and engine may have to be specially imported.

Costs

The price of these rigs depends and varies between US$ 3000 and US$ 5000.

Field experiences

Engine operated rotary jetting is mainly used in Thailand, Laos, Cambodia, Chad, Niger, Nigeria, Burkina Faso, Tanzania, Mozambique, Zambia, Mauritania, Madagascar and Nicaragua.

Reference manuals, videos, and links

- PAT-Drill - Engine powered drilling equipment and small machines – http://www.pat-drill.com

- Lone Star Bit - Engine powered drilling equipment and small machines - http://www.lonestarbit.com

- Deep Rock - Engine powered drilling equipment and small machines- http://www.deeprock.com

- Drillingfab - Engine powered drilling equipment and small machines - http://www.drillingfab.com