Difference between revisions of "Waggon Wheel system"

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | [[Image:Waggon icon.png|right| | + | [[Image:Waggon icon.png|right|80px|]] |

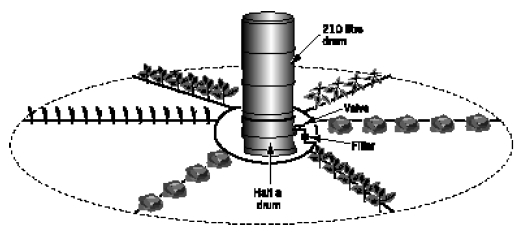

| − | [[Image:waggon wheel.jpg|thumb|right| | + | [[Image:waggon wheel.jpg|thumb|right|200px|The Waggon Wheel system. Drawing: [http://www.samsamwater.com/library.php?serie=RELMA%20Technical%20Handbook%20Series RELMA.]]] |

| − | __NOTOC__ | + | __NOTOC__ <small-title /> |

The Waggon Wheel system was developed in South Africa by Dr Gerrie Albertse in 1995. It has been used to grow vegetables and grapes in the very harsh conditions of arid South Africa. The Waggon Wheel irrigation system uses a circular arrangement of 6 drip lines radiating out from the central reservoir drum (210 litres) — hence the name Waggon Wheel. The length of each drip line is 6 m. | The Waggon Wheel system was developed in South Africa by Dr Gerrie Albertse in 1995. It has been used to grow vegetables and grapes in the very harsh conditions of arid South Africa. The Waggon Wheel irrigation system uses a circular arrangement of 6 drip lines radiating out from the central reservoir drum (210 litres) — hence the name Waggon Wheel. The length of each drip line is 6 m. | ||

| Line 10: | Line 10: | ||

Six examples are presented: the KARI drum system from Kenya, the Waggon Wheel system from South Africa, the Family, Plastro and Micro-Tal systems from Israel, and the IDE drum used in India. | Six examples are presented: the KARI drum system from Kenya, the Waggon Wheel system from South Africa, the Family, Plastro and Micro-Tal systems from Israel, and the IDE drum used in India. | ||

| − | ==Construction operations and maintenance== | + | ===Construction operations and maintenance=== |

| + | The standard drum kit system comprises a drum, control valve, a manifold and drip lines. The drum should be filled with the valve in the closed position. To irrigate it is important to open the valve fully. This allows the water to be distributed quickly through the drip lines and allows for good water distribution. | ||

| + | |||

'''System components'''<br> | '''System components'''<br> | ||

| Line 31: | Line 33: | ||

# Connect the drip lines to the manifold and the manifold to the drum outlet. | # Connect the drip lines to the manifold and the manifold to the drum outlet. | ||

| − | ==Costs== | + | ===Costs=== |

A typical cost of the homemade Waggon Wheel system is US$ 16 in South Africa. | A typical cost of the homemade Waggon Wheel system is US$ 16 in South Africa. | ||

| − | ==Acknowledgements== | + | ===Acknowledgements=== |

* Sijali, Isaya V. [http://www.samsamwater.com/library.php?serie=RELMA%20Technical%20Handbook%20Series DRIP IRRIGATION: Options for smallholder farmers in eastern and southern Africa.] RELMA, 2001. | * Sijali, Isaya V. [http://www.samsamwater.com/library.php?serie=RELMA%20Technical%20Handbook%20Series DRIP IRRIGATION: Options for smallholder farmers in eastern and southern Africa.] RELMA, 2001. | ||

Latest revision as of 05:09, 2 October 2013

The Waggon Wheel system was developed in South Africa by Dr Gerrie Albertse in 1995. It has been used to grow vegetables and grapes in the very harsh conditions of arid South Africa. The Waggon Wheel irrigation system uses a circular arrangement of 6 drip lines radiating out from the central reservoir drum (210 litres) — hence the name Waggon Wheel. The length of each drip line is 6 m.

Uses of a drum system

A drum system covering 5 beds each 1 m wide and 15 m long can be used to grow 250 plants (tomato, egg plant and similar plants requiring a spacing of 60 cm along the plant rows); 500 plants (spinach, cabbage, kale, pepper and similar plants requiring a spacing of 30 cm along the plant rows); or 1,500 plants (onion, carrot and similar plants requiring a spacing of 10 cm). The drum system also offers water storage and control through a control valve, making it possible to fill the drum for irrigating at another time.

Six examples are presented: the KARI drum system from Kenya, the Waggon Wheel system from South Africa, the Family, Plastro and Micro-Tal systems from Israel, and the IDE drum used in India.

Construction operations and maintenance

The standard drum kit system comprises a drum, control valve, a manifold and drip lines. The drum should be filled with the valve in the closed position. To irrigate it is important to open the valve fully. This allows the water to be distributed quickly through the drip lines and allows for good water distribution.

System components

- 210-litre drum

- 42 m 16 mm polyethylene pipe

- 7 pieces 15 mm tee connectors

- 1 unit 100 mm x 15 mm nipple with 2 back nuts

- 15 mm control valve (tap)

- 1.5 m 16 mm polyethylene pipes (manifold)

- 3.6 m 1.5 mm nylon braided string.

Assembly instructions

- Drill an outlet hole on the side of the drum about 10 cm from the bottom.

- Install a back nut, nipple and control valve on the outlet.

- Cut 6 pieces each 30 cm long from a 2-m PE pipe to be used in constructing the circular manifold.

- Using 6 tee connectors construct a circular manifold by connecting the tee connectors to the PE pieces, as shown in the diagram.

- Make a platform from an old drum cut in half.

- Make the drip lines by cutting six 7-m lengths of 15-mm PE and mark the positions of the holes on the pipe (30 cm apart). Heat a 50-mm nail and burn a hole through both walls of the pipe. Cut 10-cm pieces of string and thread the string through the two holes. Tie a knot on each side. Close the drip line at the end by bending the pipe and tying it with a piece of wire.

- Connect the drip lines to the manifold and the manifold to the drum outlet.

Costs

A typical cost of the homemade Waggon Wheel system is US$ 16 in South Africa.

Acknowledgements

- Sijali, Isaya V. DRIP IRRIGATION: Options for smallholder farmers in eastern and southern Africa. RELMA, 2001.