Difference between revisions of "Chlorine (NaDCC)"

| Line 1: | Line 1: | ||

| − | + | ||

[[Image:safe_water_systems_icon.png|right|80px]] | [[Image:safe_water_systems_icon.png|right|80px]] | ||

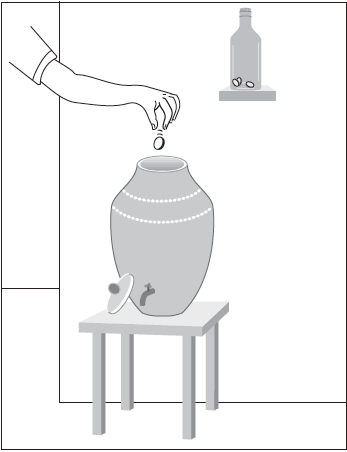

[[Image:NaDCC.jpg|thumb|right|200px|NaDCC tablet]] | [[Image:NaDCC.jpg|thumb|right|200px|NaDCC tablet]] | ||

Revision as of 03:23, 26 April 2018

NaDCC, also known as Sodium Dichloroisocyanurate or Troclosene Sodium, is one form of chlorine used for disinfection. It is often used to treat water in emergencies, and is now widely available for household water treatment.

NaDCC tablets are available with different chlorine content (e.g. 3.5 mg to 10 g) to treat from 1 to 3000 litres at a time. They are usually effervescent (meaning that escaping carbon dioxide gas causes the tablets to dissolve quickly, with a 'fizz'), allowing the tablet to dissolve in less than 1 minute.

When added to water, NaDCC releases hydrochloric acid which reacts through oxidization with microorganisms and kills them.

Three things can happen when chlorine is added to water:

- Some chlorine reacts through oxidization with organic matter and the pathogens in the water and kills them. This portion is called consumed chlorine.

- Some chlorine reacts with other organic matter and forms new chlorine compounds. This portion is called combined chlorine.

- Excess chlorine that is not consumed or combined remains in the water. This portion is called free residual chlorine (FRC). The FRC helps prevent recontamination of the treated water.

Chlorine began to be widely used as a disinfectant in the early 1900’s. It revolutionized drinking water treatment and dramatically reduced the incidence of waterborne diseases. Chlorine remains the most widely used chemical for water disinfection in the United States.

Contents

Suitable conditions

Unlimited amounts of water can be processed at a time, depending on the amount of active chlorine.

| Advantages | Disadvantages/limitations |

|---|---|

| - Some NaDCC products claim that there is no bad odour or taste after use - Highly acceptable to users because of ease of use, chlorine taste and prestige |

- Distribution system of the products should be developed - Relatively high cost |

|

|

Construction, operations and maintenance

Each product should have its own instructions for correct dosing. In general, the user adds the correct sized tablet for the amount of water to be treated, following the product instructions. Then they agitate the container, and wait for the amount of time instructed on the package, normally 30 minutes (“contact time”). The water is then disinfected and ready to be used.

The effectiveness of chlorine is affected by turbidity, organic matter, temperature and pH. For high turbidity levels, the water should first be strained through a cloth or be sedimented before adding chlorine. These processes will remove some of the suspended particles and improve the reaction between the chlorine and pathogens.

The manufacturer’s instructions for specific sodium hypochlorite products need to be followed. The required dose and contact time varies with water quality (e.g. turbidity, pH, temperature).

Use a 30 minute minimum contact time. If the pH is above 7.5, a higher Free Residual Clorine concentration of 0.6 mg/litre should be used and the contact time should be extended to 1 hour.

The contact time should be increased to 1 hour when the temperature is between 10˚ and 18˚C. It should be increased to two or more hours when the temperature falls below 10˚C.

Manufacturer’s instructions for specific NaDCC products need to be followed. The batch volume depends on size of the container used by the household.

Required dose and contact time varies with water quality (e.g. turbidity, pH, temperature). The minimum contact time to be needed is 30 minutes.

Free residual chlorine protects against recontamination.

Most users cannot determine the dosing quantity themselves; proper use requires simple instructions from the manufacturer. Users often use less than the recommended dose to save money.

Manufacturing

NaDCC tablets cannot be produced locally, but they can be bought in bulk and packaged locally.

Materials and facilities required are simply the tablets and packaging materials. Workshop space is required for packaging the tablets.

Anyone can be trained for light packaging work.

NaDCC tablets do not contain hazardous chemicals, they are safe to handle and store. Manufacturer’s instructions should be followed.

Treatment Efficiency

| Bacteria 1 | Viruses 2 | Protozoa3 | Helminths | |

|---|---|---|---|---|

| Resistance to Chlorine | low4 | moderate4 | high4 | not available |

Toxoplasma oocysts and cryptosporidium oocysts are highly resistant to chlorine disinfection 4. Chlorine alone should not be expected to inactivate these pathogens in drinking water.

Some NaDCC products claim that there is no bad odour or taste after use. Chlorine reacts with organic matter naturally present in water to form by-products such as trihalomethanes (THMs), which are potentially cancer-causing. Lantagne et al. (2008)5 indicate that THM levels produced during household chlorination may fall below World Health Organization (WHO) guideline values.

Maintenance

Chlorine requires a supply chain, market availability and regular purchase. It also requires quality control process to ensure product reliability. Sourcing suitable plastic containers to manufacture chlorine solutions can sometimes be a challenge.

Products should be protected from exposure to temperature extremes or high humidity.

Estimated Lifespan

Chlorine deteriorates over time, especially in liquid form. Liquid chlorine products should be used within 3 months of being manufactured.

If stored in strip packs, the product has a shelf-life of five years. If stored in tubs, it has a three year shelf-life.

Suppliers

Hydrachem Ltd. manufactured Oasis Water Purification tablets in the United Kingdom. Hydrachem are the largest suppliers to UNICEF.6

Medentech Ltd. manufactures Aquatabs for water disinfection, hospital surface infection control and general environmental disinfection. In Tanzania, PSI imported a single sized 20 litre-tablet that are packed locally in boxes of 36 10 tablet-strips.

Costs

| Captial Cost | Operation Cost | Replacement Cost | Estimated 5 years Cost | Cost/liter treated |

|---|---|---|---|---|

| US$ 0 | US$ 3/year | US$ 0 | US$ 15 | US$ ~0.02 |

Note: Program, transportation and education costs are not included.

Manuals, videos, and links

- Operational Guidance Briefing Note: Evidence-based Free Residual Chlorine (FRC) Targets

- Hydrachem Ltd.

- CAWST (Centre for Affordable Water and Sanitation Technology)

- Aquatabs

- Medentech Ltd.

References

- ↑ Bacteria include Burkholderia pseudomallei, Campylobacter jejuni, Escherichia coli, Salmonella typhi, Shigella dysenteriae, Shigella sonnei, Vibrio cholerae, Yersinia enterocolitica.

- ↑ Viruses include enteroviruses, adenoviruses, noroviruses, rotavirus.

- ↑ Protozoa includeEntamoeba histolytica, Giardia lamblia, Toxoplasma gondii, Cryptosporidium parvum.

- ↑ 4.0 4.1 4.2 4.3 CDC (2007)

- ↑ Lantagne et al. (2008)

- ↑ UNICEF Supply Report (2014)

Acknowledgements

This article is based on a factsheet from Centre for Affordable Water and Sanitation Technology (CAWST), which is gratefully acknowledged.

- Clasen, T. and P. Edmondson (2006). Sodium dichloroisocyanurate (NaDCC) tablets as an alternative to sodium hypochlorite for the routine treatment of drinking water at the household level. International Journal of Hygiene and Environmental Health Volume 209, Issue 2, pp. 173-181.

- Clasen, T., Saed, T., Boisson, S., Edmondson, P., and O. Shipin. (2007). Household Water Treatment Using Sodium Dichloroisocyanurate (NaDCC) Tablets: A Randomized, Controlled Trial to Assess Microbiological Effectiveness in Bangladesh. Am. J. Trop. Med. Hyg., 76(1), 2007, pp. 187–192.

- Lantagne, D.S., Blount, B. C., Cardinali, F., and R. Quick, R (2008). Disinfection by-product formation and mitigation strategies in point-of-use chlorination of turbid and non-turbid waters in western Kenya. Journal of Water and Health, 06.1, 2008.

- Molla, N., (2007). Practical Household Use of the Aquatabs Disinfectant for Drinking Water Treatment in the Low-Income Urban Communities of Dhaka, Bangladesh. Thesis, Asia Institute of Technology, School of Environment, Resources and Development.