Difference between revisions of "Screens and straining"

(Created page with "__NOTOC__ <small-title /> Image:water-side.jpg|thumb|right|200px|Screen used for removing organic debris. Photo: [http://www.optima-international.com/water-waste-water-treat...") |

(→Construction, operations and maintenance) |

||

| Line 13: | Line 13: | ||

Requires no specific social campaign as the method is widespread and is not applied directly at household level. Screening only removes larger particles (turbidity solids), therefore it cannot guarantee safe water quality. The must be applied in combination with other treatment processes. | Requires no specific social campaign as the method is widespread and is not applied directly at household level. Screening only removes larger particles (turbidity solids), therefore it cannot guarantee safe water quality. The must be applied in combination with other treatment processes. | ||

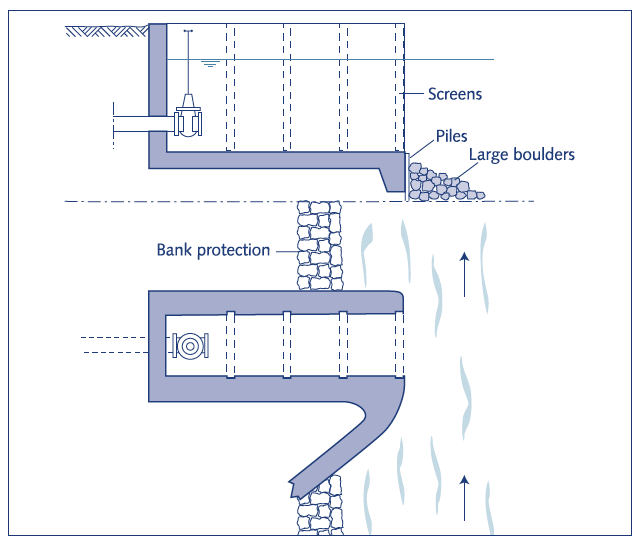

| − | [[File:river screens.png|thumb|none| | + | [[File:river screens.png|thumb|none|450px|Screens used to strain river water. Drawing: [http://www.samsamwater.com/library/TP40_11_Surface_water.pdf Surface Water Intake and Small Dams.]]] |

===Costs=== | ===Costs=== | ||

Revision as of 00:31, 4 October 2013

Screens or sieves are great for straining larger particles out of water and are a simple, but flexible technology for diverse configurations. These work well applied at (inlet of) central treatment facilities, but simple use makes it suitable for decentralized or rural applications. They can be placed at surface water inlets to prevent debris or coarse material from reaching subsequent treatment processes. Debris mostly includes organic material like leaves, duckweed and algae. In vicinity of near-urban settlements, plastic wastes are typical. Debris needs to be properly disposed and managed according to its characteristics and volume.

Suitable conditions

Drinking water, domestic use, and small-scale productive use.

Construction, operations and maintenance

The screens are mostly simple steel grids or larger sheets of screening material. For removing algae, microstrainers with openings of 10-60µm are used after screens. Although generally, those with a mesh-size of 2-8cm are preferred. Straight screens can be manufactured locally and cleaned manually. Cylindrical or drum strainers require mechanical cleaning (backwashing). They require regular debris removal, but lower debris load reduces cleaning frequency. Management requirements depend on cleaning mechanisms. Maintenance is low and can be combined with the cleaning of other facilities. Training on debris management might be required.

Requires no specific social campaign as the method is widespread and is not applied directly at household level. Screening only removes larger particles (turbidity solids), therefore it cannot guarantee safe water quality. The must be applied in combination with other treatment processes.

Costs

Costs depend on the design and the cleaning mechanism applied. Expenses can be kept low by using manual labor for cleaning and maintenance. Screens are normally donor-financed, or occasionally user-financed.

Acknowledgements

- Surface water intake and small dams, revised by Nhamo Masanganise.

- Screening. Lenntech.

- Screening and straining. Veolia Water.