Difference between revisions of "Concrete-lined earthen reservoir"

(→Acknowledgements) |

|||

| (8 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | [[Image:concrete-lined earthen diagram.jpg|thumb|right| | + | [[Image:Plastic-lined_tank_icon.png|right|80px]] |

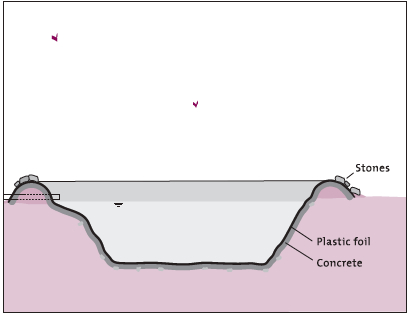

| − | + | [[Image:concrete-lined earthen diagram.jpg|thumb|right|200px|Concrete-lined earthen reservoir diagram. <br>Diagram: WHO.]] | |

| + | __NOTOC__ <small-title /> | ||

Lined earthen reservoirs can be built in natural depressions, or constructed by excavating and building a dam around the reservoir. If possible, the quantities of excavation and refill are kept nearly identical, to minimize the amount of work. The inner and outer walls of such a reservoir are always sloped, and inlets and outlets are installed during the earthwork. The walls and bottom of the reservoir must be compacted, especially the parts made by refilling. The inside of the reservoir is waterproofed by a lining of concrete, which is usually poured on-site in large slabs. The slab size is limited by the ability of the concrete slab to support its own weight when it is moved into place during construction of the reservoir. Once in place, the slabs are connected by a sealing of waterproof material. More recently, reservoirs have been constructed using a single slab of concrete, using ferrocement technology. Linings can also be made of clay, loam or plastic. | Lined earthen reservoirs can be built in natural depressions, or constructed by excavating and building a dam around the reservoir. If possible, the quantities of excavation and refill are kept nearly identical, to minimize the amount of work. The inner and outer walls of such a reservoir are always sloped, and inlets and outlets are installed during the earthwork. The walls and bottom of the reservoir must be compacted, especially the parts made by refilling. The inside of the reservoir is waterproofed by a lining of concrete, which is usually poured on-site in large slabs. The slab size is limited by the ability of the concrete slab to support its own weight when it is moved into place during construction of the reservoir. Once in place, the slabs are connected by a sealing of waterproof material. More recently, reservoirs have been constructed using a single slab of concrete, using ferrocement technology. Linings can also be made of clay, loam or plastic. | ||

| Line 6: | Line 7: | ||

'''Uses''': De-silting and storing raw water. | '''Uses''': De-silting and storing raw water. | ||

| − | ==Construction, operations and maintenance== | + | ===Resilience to changes in the environment=== |

| + | ====Drought==== | ||

| + | |||

| + | '''Effects of drought''': Badly made concrete and cracked linings (e.g. in tanks, dams, waterways, wells, and other structures). <br> | ||

| + | '''Underlying causes of effects''': Less water used for curing; Impure water used for mixing. <br> | ||

| + | '''To increase resiliency of WASH system''': Ensure adequate mixing, ratios, purity of ingredients; Minimize water content in mixture; Ensure adequate curing. | ||

| + | |||

| + | For more information on drought: [[Resilient WASH systems in drought-prone areas]] | ||

| + | |||

| + | ===Construction, operations and maintenance=== | ||

Operation of a reservoir consists of opening and closing the inlet and outlet valves and sluices, according to water need in the system and water quality at the inlet. The valves and sluices should be opened and closed at least every two months to prevent them sticking. At least once a year, the reservoir should be emptied of sediment and cleaned, and the lining inspected and disinfected with chlorine. Cracks or other damage to the lining should be repaired. Usually, the cleaning of a reservoir is a communal activity, which can be organized by a water committee that coordinates all the activities related to the system. An individual living near the reservoir can be assigned the job of caretaker. | Operation of a reservoir consists of opening and closing the inlet and outlet valves and sluices, according to water need in the system and water quality at the inlet. The valves and sluices should be opened and closed at least every two months to prevent them sticking. At least once a year, the reservoir should be emptied of sediment and cleaned, and the lining inspected and disinfected with chlorine. Cracks or other damage to the lining should be repaired. Usually, the cleaning of a reservoir is a communal activity, which can be organized by a water committee that coordinates all the activities related to the system. An individual living near the reservoir can be assigned the job of caretaker. | ||

| + | |||

| + | ===Acknowledgements=== | ||

| + | * Brikke, François, and Bredero, Maarten. [https://www.who.int/water_sanitation_health/publications/linking-technology-choice-with-o-m-in-ws/en/ Linking technology choice with operation and maintenance in the context of community water supply and sanitation: A reference document for planners and project staff] or ([http://www.washdoc.info/docsearch/title/117705 alternate link]). World Health Organization and IRC Water and Sanitation Centre. Geneva, Switzerland 2003. | ||

| + | * CARE Nederland, Desk Study: [[Resilient WASH systems in drought-prone areas]]. October 2010. | ||

Latest revision as of 05:50, 19 May 2020

Lined earthen reservoirs can be built in natural depressions, or constructed by excavating and building a dam around the reservoir. If possible, the quantities of excavation and refill are kept nearly identical, to minimize the amount of work. The inner and outer walls of such a reservoir are always sloped, and inlets and outlets are installed during the earthwork. The walls and bottom of the reservoir must be compacted, especially the parts made by refilling. The inside of the reservoir is waterproofed by a lining of concrete, which is usually poured on-site in large slabs. The slab size is limited by the ability of the concrete slab to support its own weight when it is moved into place during construction of the reservoir. Once in place, the slabs are connected by a sealing of waterproof material. More recently, reservoirs have been constructed using a single slab of concrete, using ferrocement technology. Linings can also be made of clay, loam or plastic.

Volume of reservoir: From a few cubic metres to many thousands.

Uses: De-silting and storing raw water.

Resilience to changes in the environment

Drought

Effects of drought: Badly made concrete and cracked linings (e.g. in tanks, dams, waterways, wells, and other structures).

Underlying causes of effects: Less water used for curing; Impure water used for mixing.

To increase resiliency of WASH system: Ensure adequate mixing, ratios, purity of ingredients; Minimize water content in mixture; Ensure adequate curing.

For more information on drought: Resilient WASH systems in drought-prone areas

Construction, operations and maintenance

Operation of a reservoir consists of opening and closing the inlet and outlet valves and sluices, according to water need in the system and water quality at the inlet. The valves and sluices should be opened and closed at least every two months to prevent them sticking. At least once a year, the reservoir should be emptied of sediment and cleaned, and the lining inspected and disinfected with chlorine. Cracks or other damage to the lining should be repaired. Usually, the cleaning of a reservoir is a communal activity, which can be organized by a water committee that coordinates all the activities related to the system. An individual living near the reservoir can be assigned the job of caretaker.

Acknowledgements

- Brikke, François, and Bredero, Maarten. Linking technology choice with operation and maintenance in the context of community water supply and sanitation: A reference document for planners and project staff or (alternate link). World Health Organization and IRC Water and Sanitation Centre. Geneva, Switzerland 2003.

- CARE Nederland, Desk Study: Resilient WASH systems in drought-prone areas. October 2010.