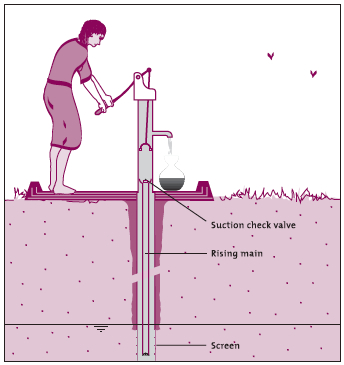

Suction plunger handpump

| |

|

|

|

|

|

|

|

|

A suction plunger handpump has its cylinder and plunger (or piston) located above the water level, usually within the pump stand itself. These pumps must be primed by pouring water on the plunger. On the up-stroke of the plunger, the pressure inside the suction pipe is reduced and atmospheric pressure on the water outside pushes the water up into the pipe. On the down-stroke, a check valve at the inlet of the suction pipe closes and water passes the plunger through an opened plunger valve. With the next upstroke, the plunger valve closes and the water is lifted up by the plunger and flows out at the top of the pump, while new water flows into the suction pipe. The operational depth of this type of handpump is limited by barometric pressure and the effectiveness of the plunger seals to about 7 m at sea level, less at higher altitudes.

Trademarks: AID Suction; Bandung, Inalsa Suction; Jetmatic Suction; Lucky, New No. 6; Rower, SYB-100; Wasp, etc.

Public Domain: No. 6 Pump

Contents

Suitable conditions

Range of depth: 0–7 m.

Yield: 0.4–0.6 litres/s at 7 m.

Area of use: Rural and low-income periurban areas where groundwater tables are within 7 m of the surface.

Construction, operations and maintenance

The operation begins with priming the pump, by pouring clean water on the plunger through the top of the pump stand. Pumping is done by moving the handle up and down, usually while standing beside the pump (with a rower pump, the user sits). Most suction handpumps can be easily operated by men, women and children.

Suction pumps are relatively easy to maintain, since most or all of the moving parts are above ground level. Maintenance can normally be done by a village caretaker or by the users themselves, using simple tools, and basic spare parts and materials (however, several brands cannot be completely maintained at local level). The basic skills needed for preventive maintenance (e.g. greasing, dismantling the pump stand, replacing spare parts, etc.) can be taught to pump caretakers quickly (from a few hours to a few days, depending on the complexity of the system, materials used, etc.).

Preventive maintenance consists of greasing the bearings every week, inspecting the interior of the pump stand once a month, and inspecting the whole pump stand once a year. Most of this work can be done by one or two people, but more people may be needed when pump parts have to be lifted out of the well or borehole. During these inspections, smaller repairs (replacement of washers, etc.) may be necessary. For major repairs (e.g. broken rising main, cracks in the welding of metal parts), more highly skilled people and specialized tools and materials may be needed.

Many suction handpumps are family pumps and are cared for by one family. For communal pumps, the user group or community will need a local committee to organize O&M tasks, including making major repairs. Private enterprises sometimes play an important role in performing repairs and selling spare parts.

Potential problems

— worn out washers, cupseals and bearings;

— excessive corrosion that causes pump rods to break, and leaks to appear in the rising mains;

— many pumps are of poor quality;

— the biggest drawback of suction pumps is that they can lift water to only about 7 m, and if the water table falls below that level, the pump becomes inoperable and must be replaced with a deep-well pump;

— contaminated water is often used to prime suction pumps;

— most pumps are designed for family use and are not sturdy enough for communal use.

Costs

From US$ 35 (Thailand, 1985), including 10 m galvanized iron drop pipe and a foot valve, to US$ 185 for a Wasp pump in India (1983 price without a suction pipe).

Acknowledgements

- Brikke, François, and Bredero, Maarten. Linking technology choice with operation and maintenance in the context of community water supply and sanitation: A reference document for planners and project staff. World Health Organization and IRC Water and Sanitation Centre. Geneva, Switzerland 2003.